Why is it called a k12 saw? This question sets the stage for an enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset.

The K12 saw, with its distinctive design and versatility, has a fascinating history and a wide range of applications. Its unique name holds a special significance that is worth exploring.

History of the K12 Saw

The K12 saw, also known as a miter saw, was invented in the mid-19th century by Richard Melhuish, a British engineer and inventor. Melhuish’s original design was a simple hand-powered saw that used a miter box to guide the blade at a precise angle.

This allowed for accurate and repeatable cuts, making it ideal for joinery and other woodworking applications.

In the early 20th century, power-driven miter saws were introduced, which significantly increased the efficiency and productivity of the tool. These saws were initially used in industrial settings, but they eventually became popular in home workshops as well.

Initial Purpose

The K12 saw was initially designed for cutting miter joints, which are angled cuts used to join two pieces of wood at a specific angle. This type of joint is commonly used in picture frames, molding, and other woodworking projects.

Use in Different Industries

In addition to woodworking, K12 saws are also used in a variety of other industries, including:

- Construction: For cutting lumber, framing, and other building materials.

- Metalworking: For cutting metal pipes, rods, and other materials.

- Automotive: For cutting exhaust pipes, suspension components, and other parts.

- HVAC: For cutting ductwork, pipes, and other materials.

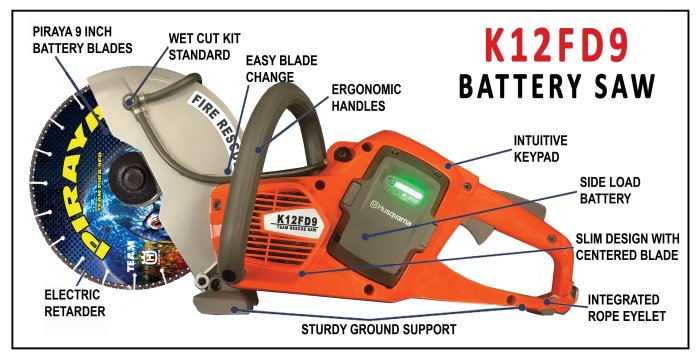

Design and Features of the K12 Saw

The K12 saw boasts a unique design that sets it apart from other saws. Its blade shape is characterized by a straight edge with a slight curve at the tip, providing both precision and versatility. The teeth configuration features alternating bevels, creating a smooth and efficient cutting action.

The handle is ergonomically designed for comfort and control, reducing fatigue during prolonged use.

Blade Shape and Teeth Configuration

The straight edge of the K12 saw’s blade enables straight, accurate cuts, while the curved tip allows for intricate cuts and curves. The alternating bevel teeth create a shearing action that minimizes tearing and splintering, resulting in clean, precise cuts.

This combination of blade shape and teeth configuration makes the K12 saw ideal for a wide range of applications.

The K12 saw gets its name from its 12-inch blade, making it ideal for cutting through bone. It’s often used in orthopedic surgeries, but it’s also versatile enough to be used in other medical fields, like in the operating room of the surgeon of gaster fell . Despite its versatility, the K12 saw remains a specialized tool that requires proper training to use effectively, especially in the hands of a skilled surgeon like the one mentioned in the article.

Materials and Performance

K12 saws are typically constructed using high-quality materials such as hardened steel or stainless steel. Hardened steel blades offer exceptional durability and edge retention, while stainless steel blades resist corrosion and are suitable for use in wet environments. The choice of material depends on the specific application and desired performance.

Applications of the K12 Saw

The K12 saw is a versatile tool used in various industries and applications. Its ability to cut through a wide range of materials with precision makes it a popular choice for many tasks.The K12 saw is commonly used in the following industries:

- Construction

- Renovation

- Woodworking

- Metalworking

- Plumbing

- Electrical

- Automotive

- Manufacturing

Within these industries, the K12 saw is used for a variety of tasks, including:

- Cutting lumber

- Trimming and shaping wood

- Cutting metal pipes and rods

- Cutting plastic

- Cutting drywall

- Cutting tile

- Cutting fiberglass

The K12 saw is particularly well-suited for cutting materials that require precision and accuracy. Its adjustable blade depth and miter angle allow for precise cuts at various angles. Additionally, the saw’s powerful motor and durable construction make it suitable for heavy-duty applications.However,

it’s important to note that the K12 saw may not be the best choice for all applications. For example, it may not be suitable for cutting very thick or hard materials, such as concrete or thick metal. Additionally, the saw can be bulky and heavy, making it less portable than other types of saws.Overall,

the K12 saw is a versatile and powerful tool that is suitable for a wide range of applications. Its precision, accuracy, and durability make it a popular choice for professionals and DIY enthusiasts alike.

Comparison to Other Saws

The K12 saw stands out among other saws due to its unique design and capabilities. Let’s compare it to three common types of saws: circular saws, jigsaws, and reciprocating saws.

Circular Saws

Circular saws are versatile and powerful tools that use a rotating circular blade to cut through various materials. They excel in making straight cuts and can be adjusted for different cutting depths. However, circular saws require more precision and can be challenging to use for intricate cuts or curves.

Jigsaws

Jigsaws employ a reciprocating blade to create precise and intricate cuts. They are ideal for cutting curves, circles, and complex shapes. However, jigsaws have limited cutting depth and can be slower than other saws for straight cuts.

Reciprocating Saws

Reciprocating saws use a back-and-forth motion to cut through materials. They are highly portable and can handle tough materials like metal and wood. However, reciprocating saws produce rougher cuts and are less precise than other saws.

| Feature | K12 Saw | Circular Saw | Jigsaw | Reciprocating Saw |

|---|---|---|---|---|

| Blade Type | Thin kerf, 12-tooth blade | Circular, various tooth counts | Reciprocating, various blade types | Reciprocating, coarse blade |

| Cutting Depth | 1-1/2 inches | Adjustable, up to 2-1/2 inches | 1/2 inch to 2 inches | Unlimited |

| Cut Quality | Fine, clean cuts | Good, rougher with higher tooth count | Precise, intricate cuts | Rough, fast cuts |

| Versatility | Good for straight and curved cuts | Excellent for straight cuts | Excellent for intricate cuts | Good for rough cuts |

| Ease of Use | Moderate, requires some skill | Moderate, requires precision | Easy, suitable for beginners | Easy, high portability |

Safety Precautions for Using a K12 Saw: Why Is It Called A K12 Saw

Operating a K12 saw requires adherence to strict safety protocols to minimize potential hazards. These precautions include wearing appropriate safety gear, maintaining a clean and organized work area, and following industry best practices.

Potential Hazards

- Kickback:Occurs when the workpiece suddenly recoils upward and toward the operator, potentially causing severe injuries.

- Cuts and lacerations:The sharp blade can inflict deep cuts or lacerations if mishandled or used improperly.

- Dust and debris:Cutting operations generate significant dust and debris, which can irritate the eyes and respiratory system.

- Electrical hazards:Ensure the saw is properly grounded and electrical connections are secure to prevent electrocution.

Safety Precautions

To mitigate these hazards, follow these safety precautions:

- Wear appropriate safety gear:Always wear safety glasses, earplugs, a dust mask, and gloves when operating the saw.

- Maintain a clean and organized work area:Keep the work area free of clutter and debris to prevent tripping hazards.

- Secure the workpiece:Clamp or hold the workpiece securely to prevent movement during cutting.

- Use sharp blades:Dull blades increase the risk of kickback and poor cuts.

- Avoid distractions:Focus solely on the task at hand to prevent accidents.

Industry Best Practices, Why is it called a k12 saw

Adhering to industry best practices further enhances safety:

- Proper training:Receive thorough training on the safe operation of the saw.

- Regular maintenance:Inspect the saw regularly for any damage or wear and replace or repair as needed.

- Follow manufacturer’s instructions:Carefully read and follow the manufacturer’s instructions for proper use and maintenance.

- Report any issues:Immediately report any malfunctions or safety concerns to a supervisor or qualified technician.

FAQ Corner

What is the origin of the K12 saw?

The K12 saw was invented in the early 20th century by a German toolmaker named Karlheinz Wendt.

Why is it called a K12 saw?

The name “K12” comes from the German word “Keilzahnung,” which means “wedge-shaped teeth.” This refers to the saw’s unique tooth design, which features wedge-shaped teeth that provide efficient cutting action.

What are the advantages of using a K12 saw?

K12 saws offer several advantages, including precision cutting, versatility, and durability. Their thin blade and fine teeth allow for accurate cuts, while their robust construction ensures longevity.