Whose job is it to inspect cranes at the jobsite – Delving into the realm of crane safety, we embark on an exploration of whose job it is to inspect cranes at construction sites. This topic holds paramount importance, as it directly impacts the well-being of workers and the integrity of infrastructure.

Throughout this discussion, we will delve into the legal requirements, industry standards, and various parties involved in ensuring the safe operation of cranes on job sites.

Responsibilities for Crane Inspections at Jobsites

Ensuring the safety and reliability of cranes at job sites requires a shared responsibility among various parties. This includes adhering to legal requirements and industry standards to minimize risks and maintain a safe working environment.

Legal Requirements

- Occupational Safety and Health Administration (OSHA) regulations mandate regular crane inspections by qualified individuals.

- The American National Standards Institute (ANSI) B30 series of standards provides comprehensive guidelines for crane inspections.

Responsible Parties

- Employersare ultimately responsible for ensuring that cranes are inspected and operated safely.

- Contractorsare responsible for selecting qualified inspectors and ensuring that inspections are conducted in accordance with applicable regulations and standards.

- Inspectorsare responsible for performing thorough inspections and documenting their findings.

Roles and Duties

- Employers must establish and implement a comprehensive crane inspection program.

- Contractors must hire qualified inspectors and provide them with necessary resources.

- Inspectors must possess the necessary training, certification, and experience to conduct thorough crane inspections.

Types of Crane Inspections

Crane inspections vary in scope and frequency depending on the type of inspection required.

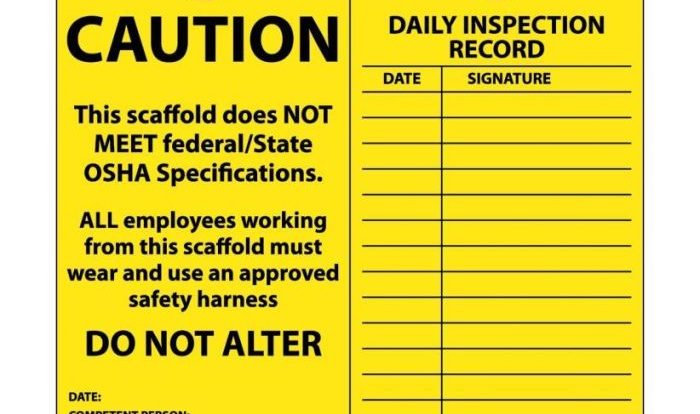

Daily Inspections

- Conducted by the crane operator before each shift.

- Focus on visual checks of critical components, such as brakes, cables, and hooks.

Weekly Inspections

- Conducted by a qualified inspector on a weekly basis.

- Involve more detailed visual inspections and functional testing.

Monthly Inspections

- Conducted by a qualified inspector on a monthly basis.

- Involve comprehensive visual inspections, functional testing, and load testing.

Annual Inspections

- Conducted by a qualified inspector on an annual basis.

- Involve the most thorough inspections, including disassembly and non-destructive testing.

Procedures for Crane Inspections

Crane inspections involve a systematic process to ensure thorough and accurate assessments.

Visual Inspections

- Inspectors visually examine all critical components for signs of damage, wear, or corrosion.

- Specific items checked include brakes, cables, hooks, and structural components.

Load Testing

- Inspectors test the crane’s capacity to lift and hold a specified load.

- Load testing ensures that the crane can safely handle the intended loads.

Functional Testing

- Inspectors test the crane’s operational functions, such as hoisting, lowering, and swinging.

- Functional testing verifies that the crane operates smoothly and efficiently.

Documentation and Corrective Actions

- Inspectors document their findings in a detailed inspection report.

- Any deficiencies or defects are identified, and corrective actions are recommended.

Documentation and Reporting: Whose Job Is It To Inspect Cranes At The Jobsite

Accurate and timely documentation of crane inspections is crucial for maintaining safety and compliance.

Documentation Requirements

- Inspection reports must include the date, time, and location of the inspection.

- Reports must detail all findings, including any deficiencies or defects.

- Maintenance logs must be kept to record repairs, modifications, and other maintenance activities.

Reporting Procedures

- Inspection reports are typically submitted to the employer or contractor.

- Any deficiencies or defects must be reported immediately to the appropriate personnel.

- Maintenance logs are used to track the history of the crane and its components.

Training and Certification

Crane inspectors must possess the necessary training and certification to perform thorough and accurate inspections.

Training Requirements

- Inspectors must receive training in crane inspection techniques, applicable regulations, and industry standards.

- Training programs typically include classroom instruction and hands-on experience.

Certification

- Inspectors can obtain certification from organizations such as the National Commission for the Certification of Crane Operators (NCCCO).

- Certification demonstrates that inspectors have met the minimum requirements for competency.

Ongoing Training and Development

- Inspectors must participate in ongoing training and professional development to stay up-to-date with industry best practices.

- This includes attending conferences, workshops, and webinars.

Technology and Innovation

Advancements in technology have enhanced the accuracy, efficiency, and safety of crane inspections.

Drones

- Drones can be used to inspect hard-to-reach areas of cranes, such as the top of the boom.

- They provide high-resolution images and videos for detailed inspections.

Sensors

- Sensors can be installed on cranes to monitor critical parameters, such as load weight, wind speed, and crane movement.

- Sensors provide real-time data that can help identify potential hazards.

Data Analytics

- Data analytics can be used to analyze inspection data and identify trends.

- This information can help improve inspection programs and reduce the risk of accidents.

General Inquiries

Who is ultimately responsible for crane safety on construction sites?

The employer or contractor who hires the crane is ultimately responsible for ensuring the safe operation of the crane on the job site.

What are the minimum qualifications for a crane inspector?

Crane inspectors should be certified by a nationally recognized organization, such as the National Commission for the Certification of Crane Operators (NCCCO) or the American Society of Mechanical Engineers (ASME).

How often should cranes be inspected?

Cranes should be inspected daily by the operator, weekly by a qualified inspector, and annually by a certified crane inspector.